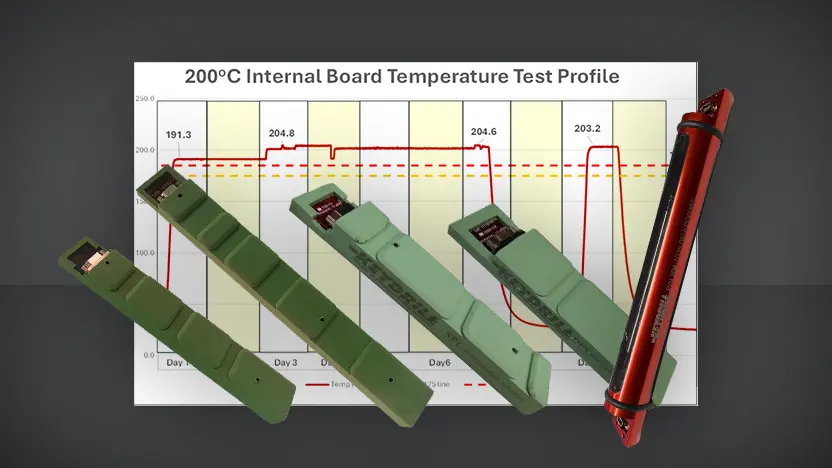

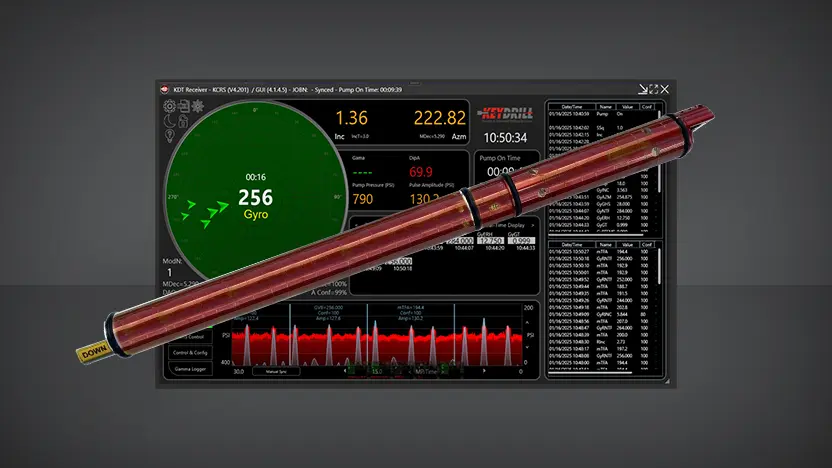

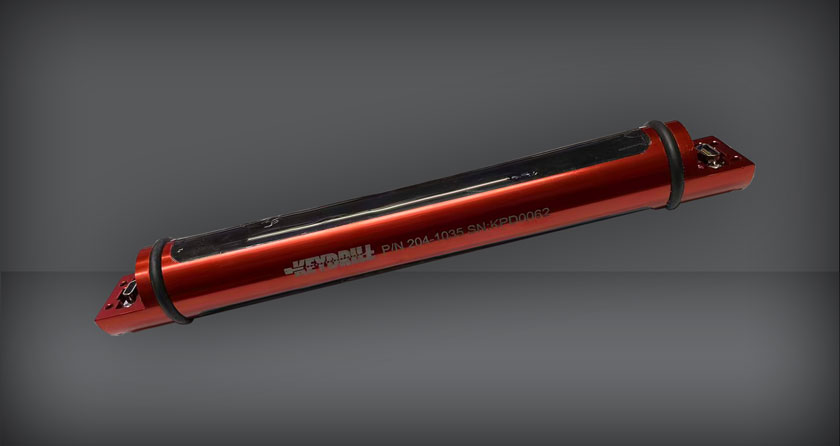

KeyDrill has extensively tested our newly designed tools with great success. Multiple field runs combined with extensive 185° shop testing has verified the new KeyDrill 185°C High-Temp MWD Technology.

KeyDrill 185°C High-Temp MWD Technology

KeyDrill has extensively tested our newly design. The new design recovered and began to function again when cooled to 192°C.

The extensive testing was prompted by multiple customers relaying excitement for not just surviving Hot Hole conditions down hole, but continuing to run at extreme conditions. Multiple field runs combined with extensive 185° shop testing has verified the new KeyDrill 185°C High-Temp MWD Technology.

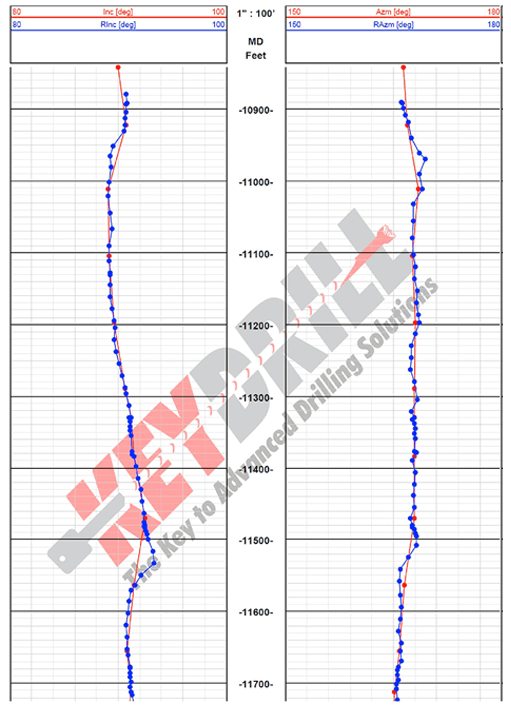

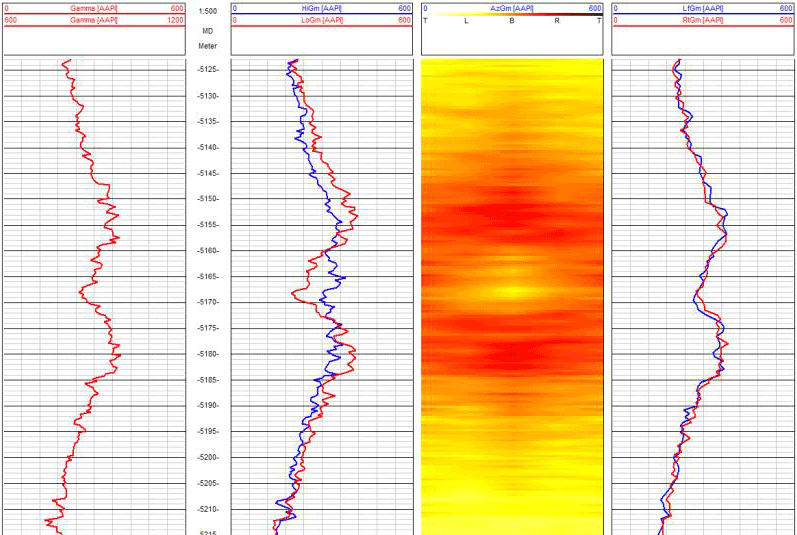

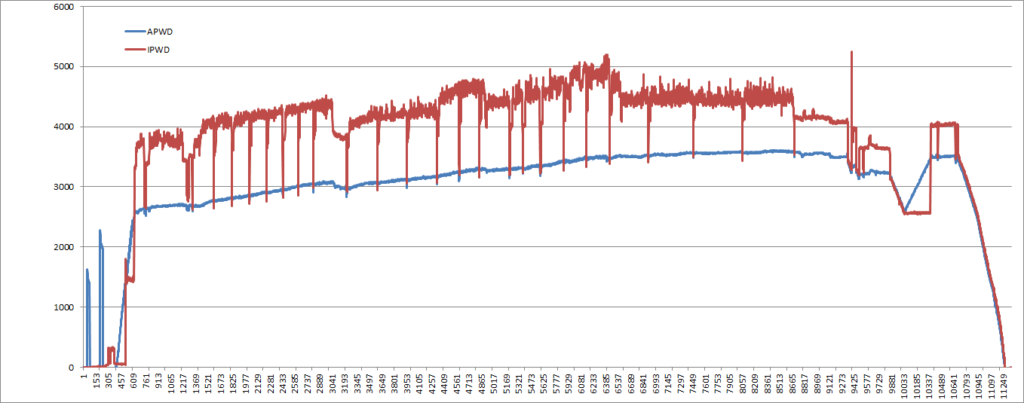

Case I:

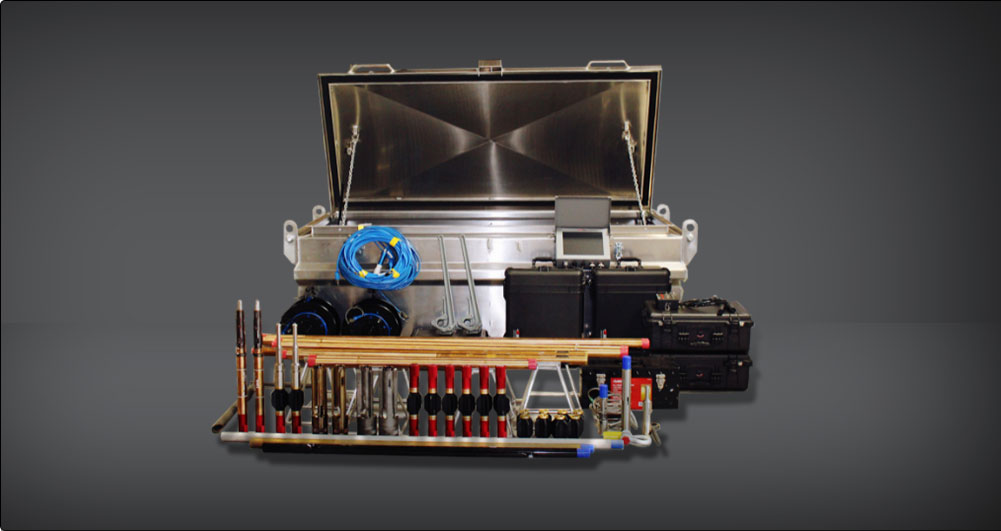

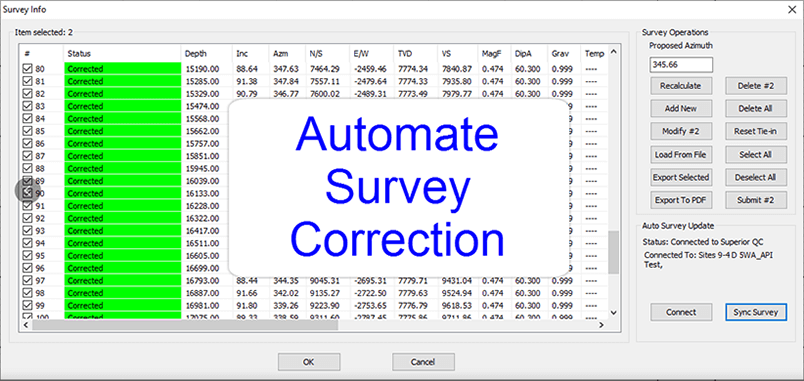

In Austin County Texas, our customer finished a “Hot Hole” well using the New KeyDrill 185°C HT-Tech full directional package and a KeyDrill 185° Azimuthal Gamma Module. The ending measured depth was 21,976 ft and circulating temperature reached the scorching temperature of 180.9°C.